Big River Steel has emerged as a leader in the steel industry, setting new standards for sustainability and innovation. With a focus on advanced technology and eco-friendly practices, this company is transforming how steel is produced and utilized. As the largest single-recycling center in North America, Big River Steel continues to inspire industries worldwide with its cutting-edge approach.

Steel production has long been associated with high energy consumption and environmental challenges. However, Big River Steel is proving that it's possible to create high-quality steel products while minimizing environmental impact. Their state-of-the-art facility combines innovative technology with a commitment to sustainability, making them a standout player in the global market.

This article delves into the story of Big River Steel, exploring its history, operations, and contributions to the steel industry. We will also examine how the company aligns with modern demands for sustainable practices, making it a model for other organizations to follow.

Read also:Kate Jackson Battling Breast Cancer With Courage And Grace

Table of Contents

- Introduction to Big River Steel

- A Brief History of Big River Steel

- Core Operations and Production Process

- Technological Innovations Driving Success

- Commitment to Sustainability

- Big River Steel's Impact on the Industry

- Market Reach and Expansion Plans

- Overcoming Challenges in the Steel Industry

- Future Goals and Vision

- Conclusion

Introduction to Big River Steel

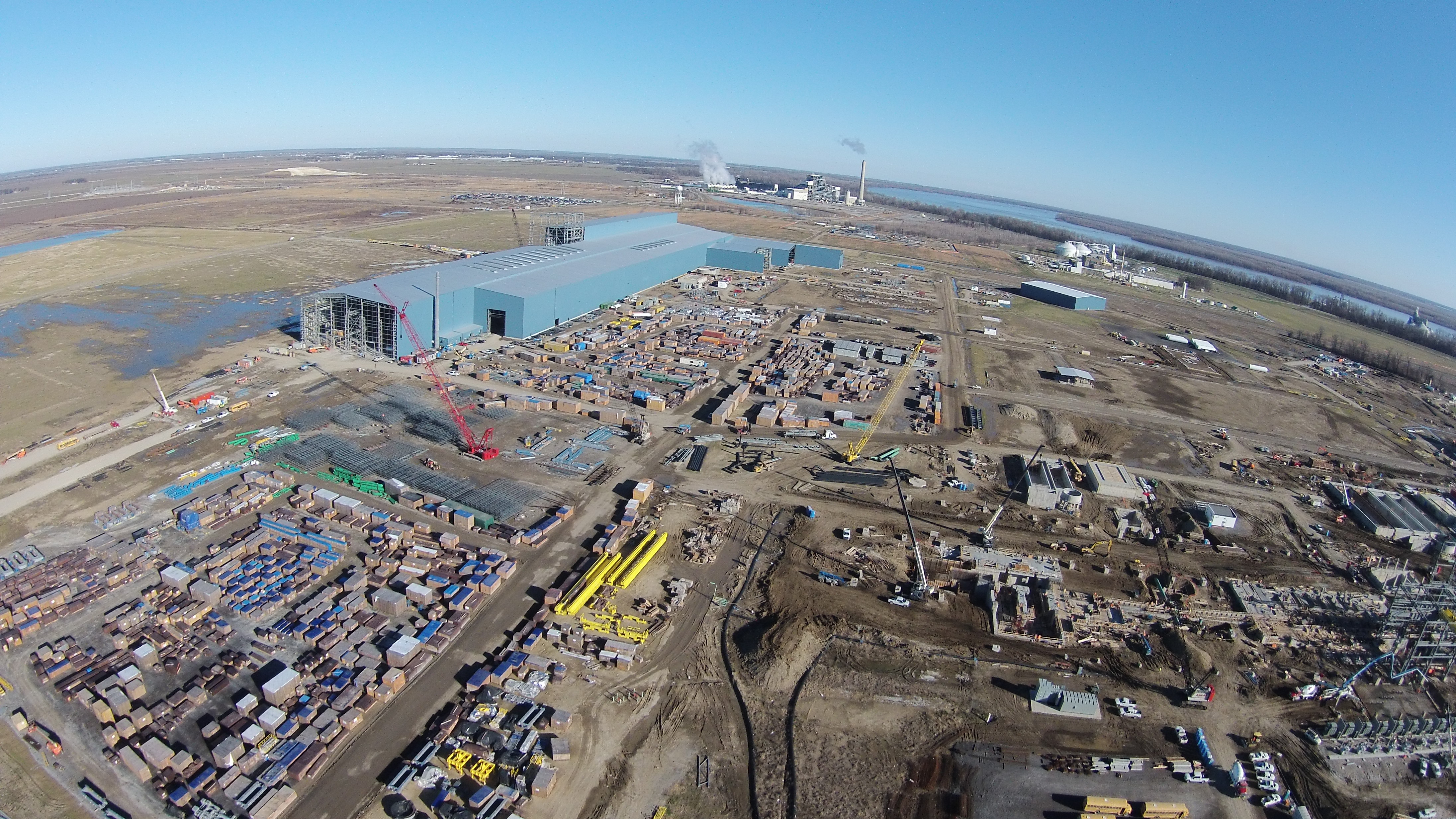

Big River Steel is reshaping the steel industry with its innovative approach and dedication to sustainability. Established in 2015, the company quickly gained recognition for its advanced electric arc furnace (EAF) technology and environmentally friendly practices. Located in Osceola, Arkansas, the facility stands as a testament to the company's vision of creating a cleaner and more efficient steel production process.

The company's success lies in its ability to blend cutting-edge technology with a commitment to reducing carbon emissions. By utilizing recycled scrap metal as its primary raw material, Big River Steel significantly lowers its environmental footprint. This approach not only aligns with global sustainability goals but also enhances the company's competitiveness in the market.

A Brief History of Big River Steel

Big River Steel was founded with a mission to revolutionize steel production. The company's journey began in 2015 when it opened its doors in Osceola, Arkansas. From the outset, the founders envisioned a facility that would set new standards for efficiency and sustainability in the steel industry. Their vision quickly became a reality as the company grew to become one of the largest single-recycling centers in North America.

Over the years, Big River Steel has expanded its operations and capabilities. The company has invested heavily in research and development, ensuring that it remains at the forefront of technological advancements in the steel industry. This commitment to innovation has allowed Big River Steel to maintain its competitive edge and establish itself as a leader in sustainable steel production.

Core Operations and Production Process

The production process at Big River Steel is designed to maximize efficiency and minimize environmental impact. The company employs an electric arc furnace (EAF) system, which uses electricity to melt scrap metal. This method is significantly more energy-efficient than traditional blast furnaces and reduces greenhouse gas emissions by up to 60%.

Key aspects of the production process include:

Read also:Unveiling The Oscar Journey Of Chris Evans

- Utilization of recycled scrap metal as the primary raw material

- Employment of advanced EAF technology for melting and refining

- Implementation of water recycling systems to conserve resources

- Continuous monitoring and improvement of energy efficiency

Technological Innovations Driving Success

Big River Steel's success is largely attributed to its adoption of cutting-edge technology. The company invests heavily in research and development to ensure that its production processes remain at the forefront of innovation. Some of the key technological advancements include:

1. Smart Manufacturing Systems: These systems enable real-time monitoring and control of production processes, ensuring optimal efficiency and quality.

2. Artificial Intelligence (AI) and Machine Learning: AI-powered algorithms help predict equipment maintenance needs and optimize production schedules.

3. Advanced Material Science: The company collaborates with leading research institutions to develop new steel alloys with enhanced properties.

Commitment to Sustainability

Sustainability is at the core of Big River Steel's operations. The company is committed to reducing its environmental impact through various initiatives, including:

- Recycling over 3 million tons of scrap metal annually

- Reducing carbon emissions by utilizing renewable energy sources

- Implementing water conservation measures to minimize resource usage

- Partnering with local communities to promote environmental awareness

Big River Steel's efforts have earned it numerous awards and recognitions for its contributions to sustainability in the steel industry. The company continues to explore new ways to further reduce its environmental footprint and inspire others to follow suit.

Big River Steel's Impact on the Industry

The influence of Big River Steel extends beyond its own operations. By demonstrating the viability of sustainable steel production, the company has inspired others in the industry to adopt similar practices. Its success serves as a model for other organizations seeking to balance profitability with environmental responsibility.

Key impacts of Big River Steel on the industry include:

- Encouraging the adoption of EAF technology by other steel producers

- Promoting the use of recycled materials in steel production

- Advancing research and development in sustainable manufacturing processes

Market Reach and Expansion Plans

Big River Steel's products are in high demand across various industries, including automotive, construction, and energy. The company's commitment to quality and sustainability has earned it a strong reputation among customers worldwide. To meet growing demand, Big River Steel has announced plans to expand its operations and increase production capacity.

The expansion plans include:

- Construction of additional facilities in strategic locations

- Investment in new technology to enhance production efficiency

- Expansion of the company's sales and distribution network

Overcoming Challenges in the Steel Industry

Despite its success, Big River Steel faces several challenges in the highly competitive steel industry. These challenges include fluctuating raw material prices, increasing regulatory requirements, and intense competition from both domestic and international producers.

To address these challenges, the company focuses on:

- Developing long-term partnerships with suppliers to secure stable raw material supplies

- Staying ahead of regulatory changes through proactive compliance measures

- Continuously improving its products and services to maintain a competitive edge

Future Goals and Vision

Looking ahead, Big River Steel aims to continue leading the charge in sustainable steel production. The company's future goals include further reducing its carbon footprint, expanding its product offerings, and enhancing its contributions to the communities it serves.

Key elements of the company's vision include:

- Investing in renewable energy sources to power its facilities

- Collaborating with industry partners to develop new sustainable technologies

- Supporting educational initiatives to promote STEM fields and environmental awareness

Conclusion

Big River Steel has established itself as a leader in the steel industry through its commitment to innovation and sustainability. By utilizing advanced technology and eco-friendly practices, the company has set new standards for steel production. Its impact on the industry extends beyond its own operations, inspiring others to adopt similar approaches.

We invite you to share your thoughts on Big River Steel's contributions to the steel industry. Leave a comment below or explore other articles on our site to learn more about sustainable practices in various industries. Together, we can create a cleaner and more efficient future for generations to come.